DRB Automotive Co., Ltd. Main menu

All Menu

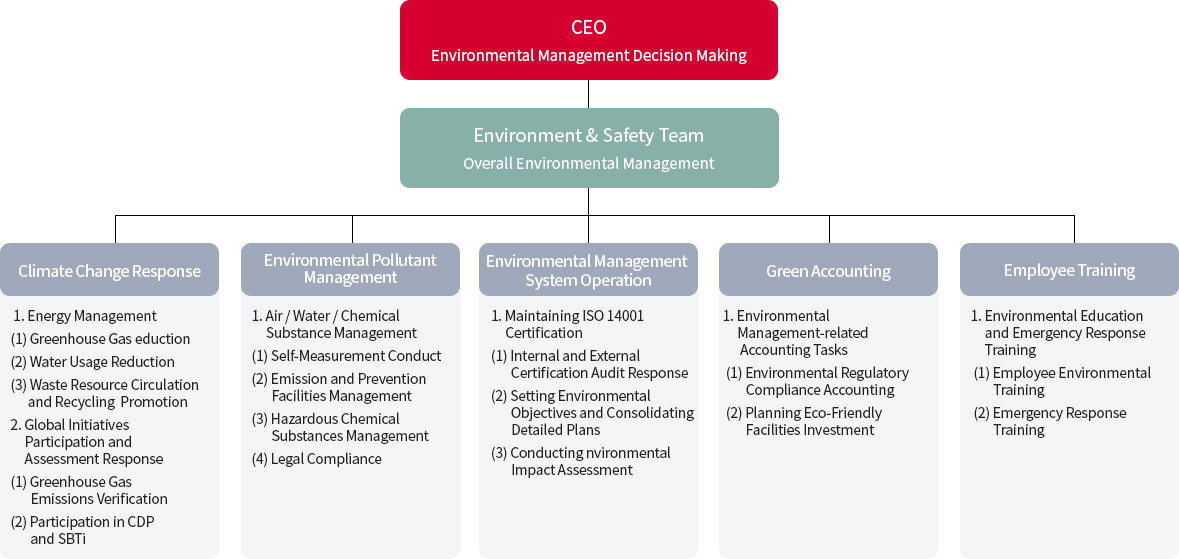

DRB Automotive has an Occupational Health and safety Committee, which holds meetings quarterly and is chaired by the health and safety director (CEO). Employees’ health and safety management requirements are collected on a regular basis through this system, and improvements are brought about through communication and information exchange. Major issues are submitted to the ESG Committee within the Board of Directors for final decisions. We also monitor whether the final decision is systematically executed through a specialized health and safety management organization for each domestic and overseas affiliate and business site.

For health and safety management, DRB Automotive designates health and safety department and health and safety managers. These managers are responsible for all activities related to health and safety management, including establishing and maintaining a health and safety management system, preparing for the acquisition of permits for the installation and operation of health and safety facilities, managing industrial accidents occurring during business operations, identifying and mitigating health and safety risks, expanding health and safety management, handling health and safety-related grievances, and engaging in external collaboration activities.

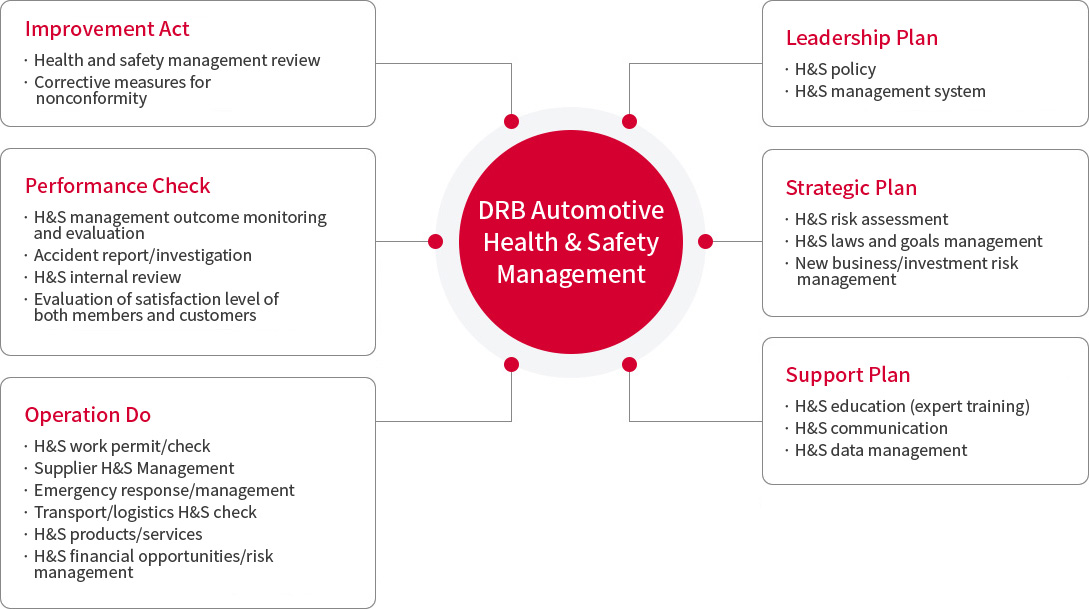

DRB Automotive has adopted a management policy based on a health and safety management system in accordance with global standards, obtaining ISO 45001 certification to minimize health and safety impact. We have established a system that specifies objectives, departments, plans, tasks, and procedures, efficiently allocating and managing management resources.

We systematically implement the PDCA (Plan-Do-Check-Act) cycle annually as the cornerstone of our operations. Our strategic focus encompasses the following: First, establish and monitor detailed health and safety management plans, considering relevant issues and stakeholder feedback. Second, develop improvement plans for negative health and safety impacts caused by the entire production process. Third, assess the accuracy and transparency of the health and safety management system through a third-party audit organization.

* Verification cycle: once per year (post-assessment), once every three years (certification inspection)

Last, review health and safety risks and business impacts on stakeholders and incorporate them into the overall business management strategy.